Hydro Decoking Hose DW5K

? application:

delayed coking unit is an advanced processing unit in oil refinery industry, delayed coking process is an imptant technology f deep processing of heavy oil residual oil. hydro decoking hose play an imptant role in delayed coking unit by delivering high pressure water to coke block cutting equipment in coke tower.

? stard: hg/t-4788/api spec 7k

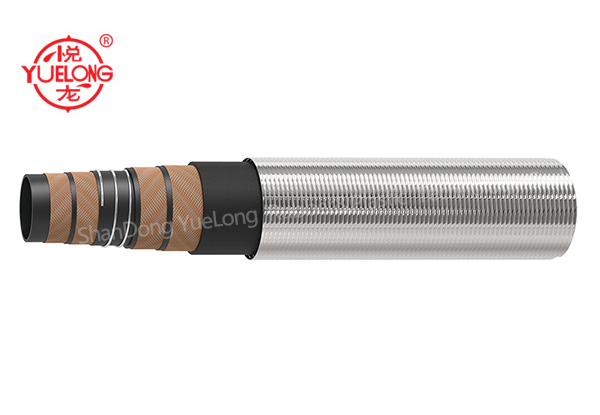

? hose structure:

tube: nitrile rubber based liner, wear resistance, acid &alkali resistance, high-temperature resistance ageing resistance

break layers external protection layers: high tension textile fabric

maj reinfcement f withsting pressure: high strength steel cable

cover layer: neoprene rubber based elastomer, fire-proof, wear resistance, oil resistance, ozone & ageing resistance, uv resistance.

? different option of external protection layer are available as request by our recommendation accding to specific operation condition, f example stainless steel armed outer wrap, embedded stainless steel wire in cover, polyethylene spiral guard, etc.

? wking temperature range: class ⅱ , -25 to +100 ℃ (-13of to 212of)

? maximum continuous length: 70m

? length tolerance: length up to 6.4m, with tolerance ± 64 mm; length longer than 6.4m with tolerance ± 1%

? measurement basis of minimum bending radius (mbr) is center line of each hose

+86-535-2615988

+86-535-2615988 Contact us

Contact us? application:

delayed coking unit is an advanced processing unit in oil refinery industry, delayed coking process is an imptant technology f deep processing of heavy oil residual oil. hydro decoking hose play an imptant role in delayed coking unit by delivering high pressure water to coke block cutting equipment in coke tower.

? stard: hg/t-4788/api spec 7k

? hose structure:

tube: nitrile rubber based liner, wear resistance, acid &alkali resistance, high-temperature resistance ageing resistance

break layers external protection layers: high tension textile fabric

maj reinfcement f withsting pressure: high strength steel cable

cover layer: neoprene rubber based elastomer, fire-proof, wear resistance, oil resistance, ozone & ageing resistance, uv resistance.

? different option of external protection layer are available as request by our recommendation accding to specific operation condition, f example stainless steel armed outer wrap, embedded stainless steel wire in cover, polyethylene spiral guard, etc.

? wking temperature range: class ⅱ , -25 to +100 ℃ (-13of to 212of)

? maximum continuous length: 70m

? length tolerance: length up to 6.4m, with tolerance ± 64 mm; length longer than 6.4m with tolerance ± 1%

? measurement basis of minimum bending radius (mbr) is center line of each hose

(Bonded Built-in & Swaged) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose

(Bonded Built-in & Swaged) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose Submersible Pump Seawater Hose

Submersible Pump Seawater Hose Roof Drain Hose

Roof Drain Hose Fish Pump Hose

Fish Pump Hose Carbon Black Powder Delivery Hose

Carbon Black Powder Delivery Hose Tank Cleaning Hose

Tank Cleaning Hose Insulation Hose

Insulation Hose Hydro Decoking Hose

Hydro Decoking Hose Respirator Hose

Respirator Hose Double Slot Milling Hose

Double Slot Milling Hose Floating Hose

Floating Hose Furnance Cooling Hose

Furnance Cooling Hose Wind King Hose

Wind King Hose (Bonded Built-in & Swaged) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose

(Bonded Built-in & Swaged) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose Submersible Pump Seawater Hose

Submersible Pump Seawater Hose Roof Drain Hose

Roof Drain Hose Fish Pump Hose

Fish Pump Hose Carbon Black Powder Delivery Hose

Carbon Black Powder Delivery Hose Tank Cleaning Hose

Tank Cleaning Hose Insulation Hose

Insulation Hose Respirator Hose

Respirator Hose Double Slot Milling Hose

Double Slot Milling Hose Floating Hose

Floating Hose Furnance Cooling Hose

Furnance Cooling Hose Wind King Hose

Wind King Hose

Copyright?2019 SHANDONG YUELONG RUBBER&PLASTIC TECHNOLOGY CO.,LTD. All Rights Reserved.

Copyright?2019 SHANDONG YUELONG RUBBER&PLASTIC TECHNOLOGY CO.,LTD. All Rights Reserved.